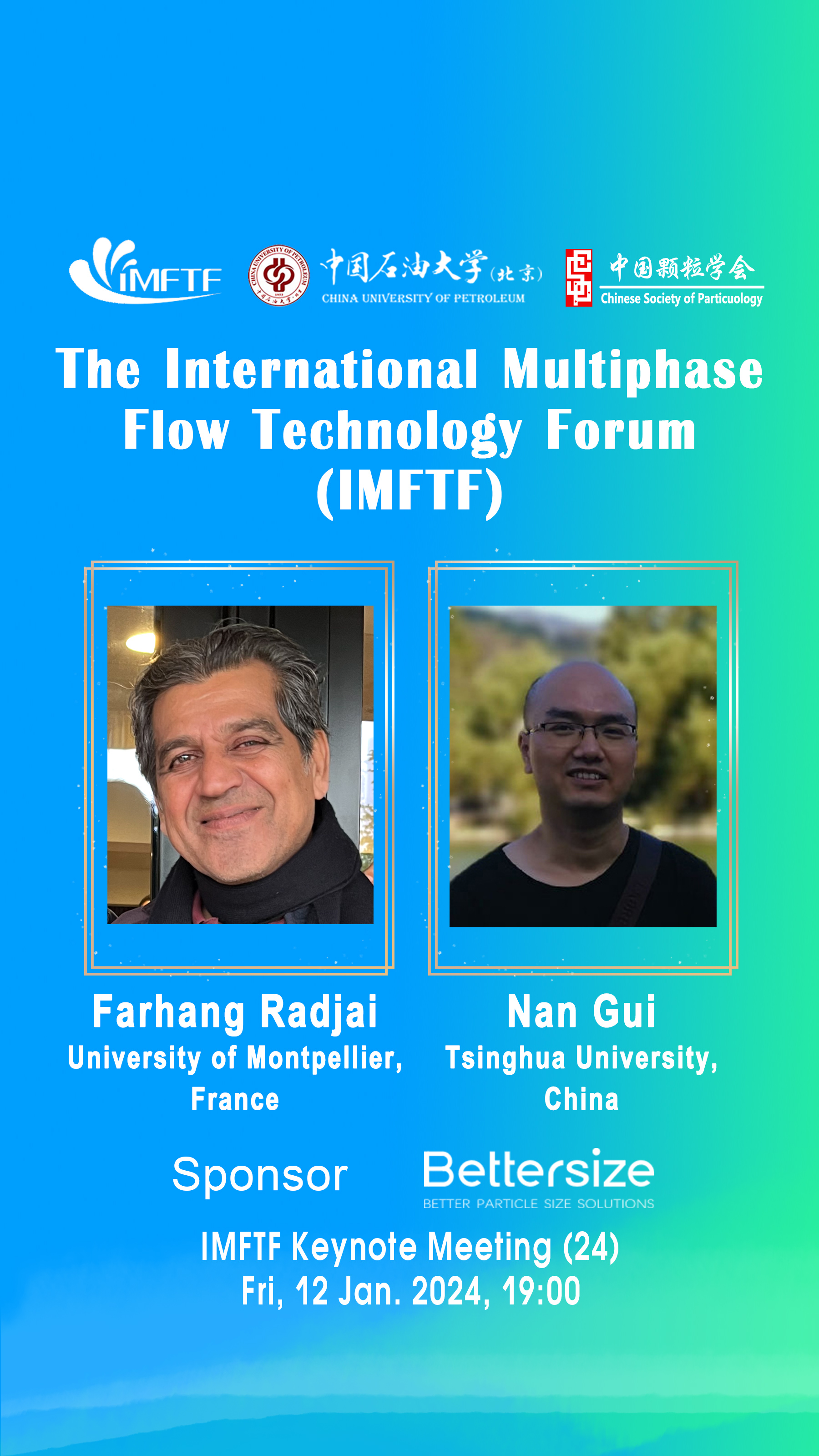

IMFTF Keynote Meeting (24) Schedule

Date & Time: Fri, 12 Jan. 2024, 19:00

Chair:

Professor Jun Yao, College of Mechanical and Transportation Engineering, China University of Petroleum (Beijing)

Opening:

(19:00 – 19:05 Beijing Time)

Programme:

Keynote Speech-1

(19:05 – 19:45 Beijing Time)

Research Director

Farhang Radjai

University of Montpellier, France

Q&A

(19:45 – 20:00 Beijing Time)

Keynote Speech-2

(20:00 – 20:40 Beijing Time)

Associate Professor

Nan Gui

Tsinghua University, China

Q&A

(20:40 – 20:55 Beijing Time)

Discussions, closing

(20:55 – 21:00 Beijing Time)

TBD

Platform: Zoom:

https://us06web.zoom.us/j/82587486233?pwd=nYyXLNj703jTPWOqnPdpWo3xBboOmw.1

Meeting ID: 825 8748 6233

Passcode: 0112

Organizer

HOST

International Multiphase Flow Technology Forum

China University of Petroleum-Beijing

Chinese Society of Particuology

SPONSOR

BETTER PARTICLE SIZE SOLUTIONS

View Live

Channel(视频号)

Bilibili(b站)

Weibo(微博)

Youtube

Keynote Speech-1

Particle fracture in granular materials by particle dynamics simulations

Farhang Radjai

Research Director

National Center for Scientific Research (CNRS), University of Montpellier, France

Most granular processes involve particle damage and fracture. Nevertheless, the mechanisms of particle fracture in granular flows and its effects on the texture and mechanical response of granular materials remain poorly understood. Recent developments in particle dynamics simulations based on the discrete element method and continuum models provide physical insights that open the way for a better modeling of processes involving particle fracture. After a brief review of methods developed for the simulation of particle fracture, I present several examples of simulations and parametric studies used to analyze the breakage of a single particle and its scaling with impact energy, the evolution of particle size distribution in cascading flows in a rotating drum and its scaling with system parameters, the evolution of particle size distribution in quasi-static flows and its effect on the flow behavior, the cushioning effect, self-similar fragment size distributions and particle shapes arising from both single-particle and collective particle breakage, and fracture of cemented granular materials.

References:

R. Affes, J.-Y. Delenne, F. Radjai, Y. Monerie, V. Topin (2012), ”Tensile strength and fracture of cemented granular aggregates” Eur. Phys. J. E 35, 117.

D.-H. Nguyen, E. Azéma, P. Sornay, F. Radjai (2015), “Bonded-cell model for particle fracture", Phys. Rev. E 91, 022203, pp. 1–9.

E. Chichti, V. Lullien-Pellerin, M. George, F. Radjai, R. Affès, JY Delenne (2016), “Bottom-up model for understanding the effects of wheat endosperm microstructure on its mechanical strength", Journal of Food Engineering 190, 40–47.

D. Cantor, E. Azéma, P. Sornay, F. Radjai (2017), “Three-dimensional bonded-cell model for grain fragmentation", Computational Particle Mechanics 4, 441-450.

H. Laubie, F. Radjai, R. Pellenq, F.-J. Ulm (2017), “Stress transmission and failure in disordered porous media", Physical Review Letters 119, 075501.

D.-H. Nguyen, E Azéma, P. Sornay, F. Radjai (2018), “Rheology of granular materials composed of crushable particles", The European Physical Journal E 41, 50.

L.F. Orozco, J.Y. Delenne, P. Sornay, F. Radjai (2019), “Discrete-element model for dynamic fracture of a single particle", Int. J. Sol. Struct. 166, 47-56.

L.F. Orozco, D.H. Nguyen, J.-Y. Delenne, P. Sornay, F. Radjai (2019), “Discrete- element simulations of comminution in rotating drums: Effects of grinding media", Powder Technology 362, 157-167.

L. F. Orozco, J.-Y. Delenne, P. Sornay, F. Radjai (2020), “Scaling behavior of particle breakage in granular flows inside rotating drums", Phys. Rev. E 101, 052904.

X. Frank, F. Radjai, S. Nezamabadi, J.-Y. Delenne (2020), “Tensile strength of granular aggregates: Stress chains across particle phase versus stress concentration by pores", Phys. Rev. E 102, 022906.

N. Blanc, C. Mayer-Laigle, X. Frank, F. Radjai, J.-Y. Delenne (2020), “Evolution of grinding energy and particle size during dry ball-milling of silica sand", Powder Technology 376, 661-667.

Keynote Speech-2

A GPU-DEM model for the pebble flow and heat transfer studies in HTRG-packed bed

Nan Gui

Associate Professor

Tsinghua University, China

The dynamics and heat transfer simulations in the pebble bed of a high-temperature gas-cooled reactor (HTGR) are an important aspect of reactor design. Based on the discrete element method (DEM) and GPU parallel computing, a GPU-DEM model is developed to simulate the large-scale pebble flow or the heat transfer in a packed pebble bed of HTGRs. The heat transfer model is developed based on the dynamics model. A grid-based neighbor searching algorithm is used for the contact model of particles and the heat transfer models. Neural networks and empirical fittings are incorporated to calculate the radiation view factors, which can improve computational efficiency. Additionally, Unified Memory Addressing (UMA) technology is employed in program design to enhance data transmission management between the host and device. At present, the verification of the particle dynamics model has been completed, and the verification of the heat transfer model is being carried out. The results demonstrated that the model can achieve a single-core speedup ratio of more than 200 times with GPU acceleration when single-precision floating-point numbers are used for calculation. It demonstrates great potential in dealing with large-scale pebble flow and heat transfer challenges in HTGRs.

References:

Cundall P A, Strack O D. A discrete numerical model for granular assemblies. Géotechnique, 1979,29(1).

Horabik J, Molenda M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosystems Engineering, 2016,147:206-225.

Shengyao J, Jiyuan T, Xingtuan Y, et al. A review of pebble flow study for pebble bed high temperature gas-cooled reactor. Experimental and Computational Multiphase Flow, 2019,1(3).

Wu H, Gui N, Yang X, et al. Parameter analysis and wall effect of radiative heat transfer for CFD-DEM simulation in nuclear packed pebble bed. Experimental and computational multiphase flow, 2020,3(4):250-257.

Nvidia C. Nvidia CUDA C programming guide. Nvidia Corporation, 2011,120(18):8.

Radeke C A, Glasser B J, Khinast J G. Large-scale powder mixer simulations using massively parallel GPU architectures. Chemical Engineering Science, 2010,65(24):6435-6442.

He Y, Bayly A E, Hassanpour A, et al. A GPU-based coupled SPH-DEM method for particle-fluid flow with free surfaces. Powder Technology, 2018,338:548-562.

Mueller G E. A simple method for determining sphere packed bed radial porosity. Powder Technology, 2012,229:90-96.

Peng Z, Doroodchi E, Moghtaderi B. Heat transfer modelling in Discrete Element Method (DEM)-based simulations of thermal processes: Theory and model development. Progress in Energy and Combustion Science, 2020,79:100847.

Zou Q, Gui N, Yang X, et al. A GPU-based DEM model for the pebble flow study in packed bed: Simulation scheme and validation. Powder Technology, 2023:118441.

Zou Q, Gui N, Yang X, et al. Comparative Study on the Numerical Methods for View Factor Computation for Packed Pebble Beds: Back Propagation Neural Network Methods Versus Monte Carlo Methods. Journal of Heat Transfer, 2021,143(8).

De Beer M. Characterisation of thermal radiation in the near-wall region of a packed pebble bed., 2014.

Rousseau P G, du Toit C G, van Antwerpen W, et al. Separate effects tests to determine the effective thermal conductivity in the PBMR HTTU test facility. Nuclear Engineering and Design, 2014,271:444-458.

Zhou Z Y, Yu A B, Zulli P. A new computational method for studying heat transfer in fluid bed reactors. Powder Technology, 2010,197(1-2):102-110.

Johnson E, Baker D, Tari I, et al. Development of view factor correlations for modeling thermal radiation in solid particle solar receivers using CFD-DEM. AIP Conference Proceedings, 2019,2126(1).